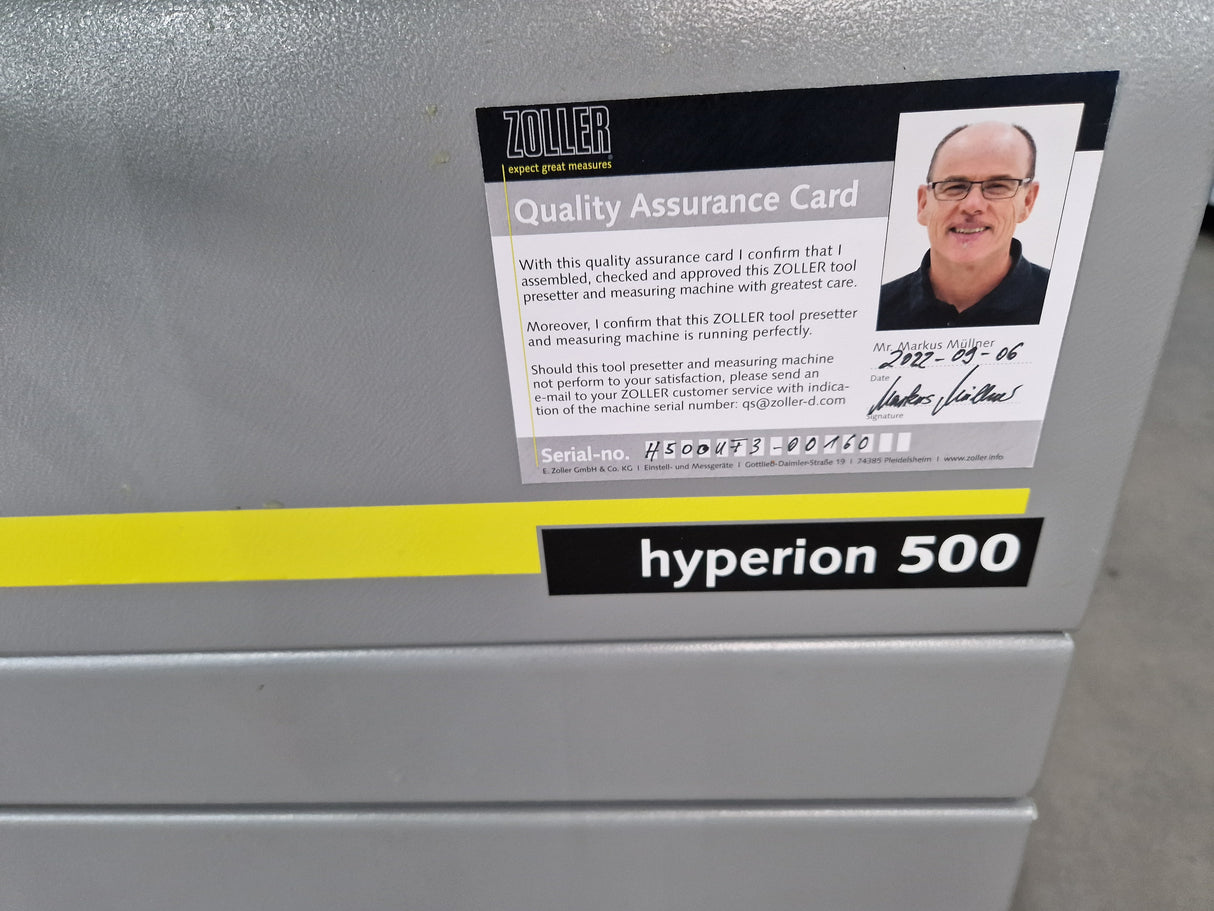

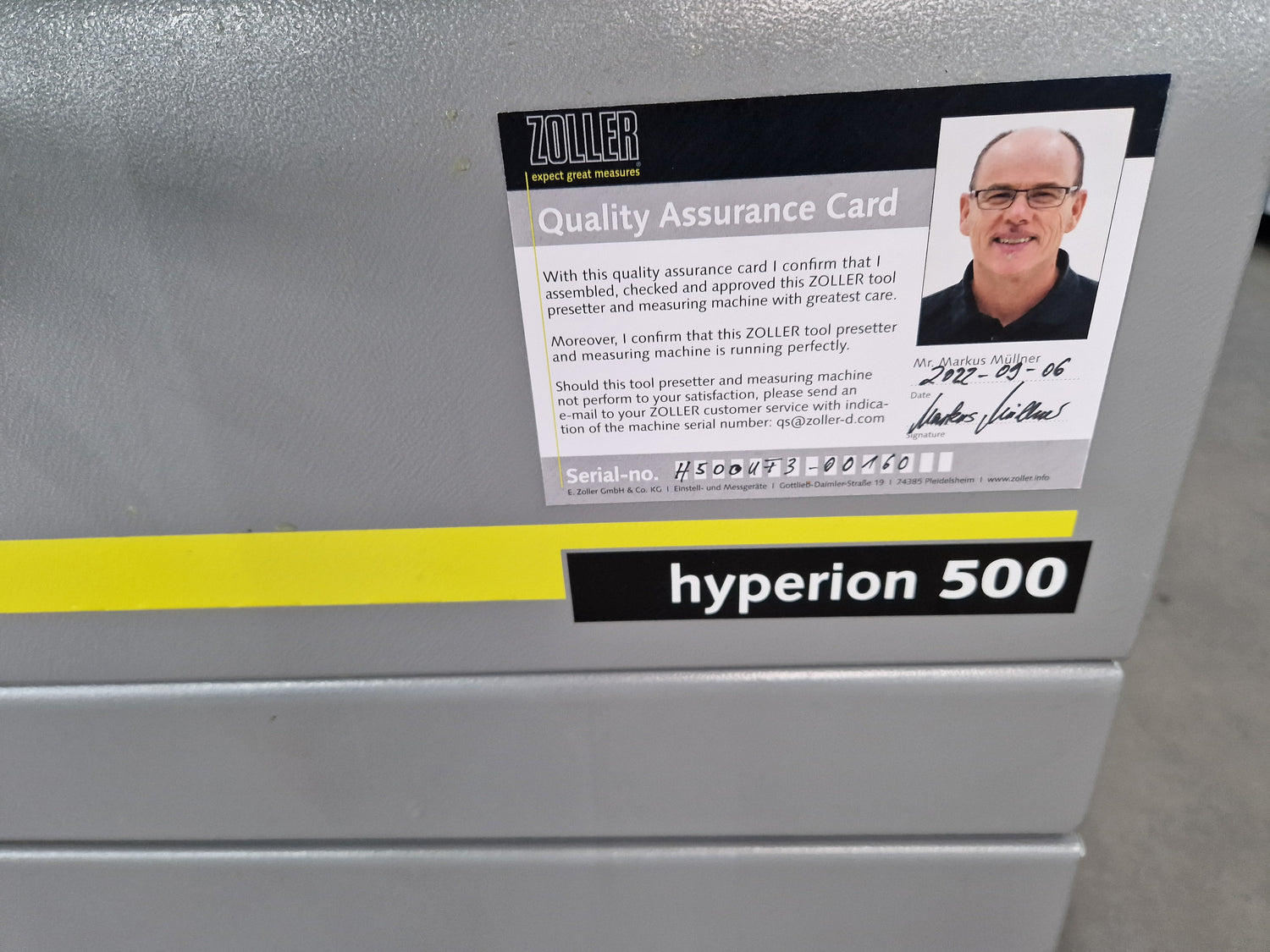

Zoller Hyperion 500 Calibration Machine | High Precision Tool Measurement

Brand: Zoller

Sold By: Swisstools

Location: 960, Avenue des Amaranches Zone Ecotec 74460 MARNAZ FRANCE

Brand: Zoller

Sold By: Swisstools

Location: 960, Avenue des Amaranches Zone Ecotec 74460 MARNAZ FRANCE

Zoller Hyperion 500 Calibration Machine | High Precision Tool Measurement is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Description

Description

€€ Price is negotiable

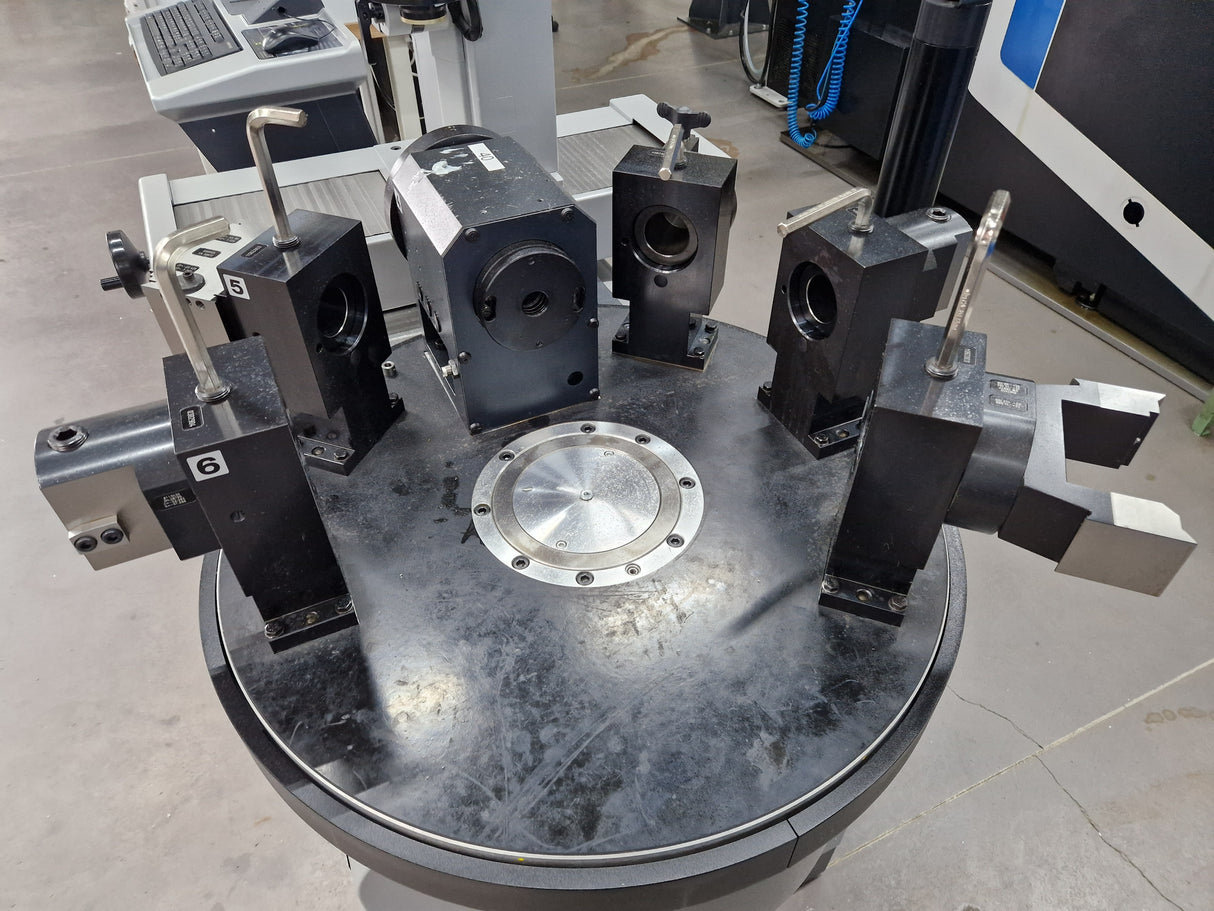

The Zoller Hyperion 500 Advanced Tool Measurement and Calibration Machine exemplifies engineering excellence, tailored to deliver unparalleled accuracy and reliability in tool calibration and measurement for high-stakes manufacturing environments. This machine is built with advanced CNC technology and features a high-precision pneumatic system that ensures consistent pressure application and exact alignment, crucial for achieving precise measurements.

Key Technical Specifications:

- Dimensions: 2140 mm width, 1130 mm depth, 1780 mm height, accommodating various industrial settings.

- Weight Capacity: Capable of handling tools up to 50 kg, supporting a broad range of measurement and calibration tasks.

- Voltage Requirements: Versatile dual voltage system (100-120/200-240 V~), catering to international power standards.

- Frequency: Operates efficiently at both 50 and 60 Hz, adaptable to varied electrical infrastructures.

- Measurement Tolerance: Offers ultra-precise measurement capabilities within ±0.002 mm, essential for precision engineering.

- Operational Environment: Operates optimally within a temperature range of 5°C – 35°C and humidity levels of 5% – 90% non-condensing, making it suitable for diverse operational climates.

- Multi-Axis Control: Features up to 4 axes for comprehensive tool analysis, with an optional rotational axis for detailed tool examination.

- Safety Features: Equipped with emergency stops and safety shields, ensuring secure operations and enhanced workplace safety.

- Connectivity: Includes USB and network interfaces for seamless integration into existing systems, facilitating data transfer and system management.

- Software: Incorporates Zoller's Pilot 3.0 software, which offers an intuitive interface and advanced analysis tools for streamlined operations and precise control.

- Pressure System: Integrated pneumatic system maintains precise tool positioning and stability during measurements.

- Maintenance Features: Optional pressurized air cleaning system to maintain optimal cleanliness and functionality of the machine.

Application and Usage: Designed to integrate seamlessly into industrial settings requiring meticulous precision such as aerospace, automotive, and precision engineering sectors, the Hyperion 500 ensures that every tool is measured with the highest accuracy. This significantly enhances the quality and consistency of production outputs, making the Hyperion 500 an indispensable asset for modern manufacturing facilities.

Shipping & Delivery

Shipping & Delivery

As an official launch, we are giving our customers free shipping for the first month!

Neem contact op als er interesse is voor dit product.

Kinderhuissingel 6A

2013AS Haarlem, NL

hello@hectool.com

+31(0)852104830

€€ Price is negotiable

The Zoller Hyperion 500 Advanced Tool Measurement and Calibration Machine exemplifies engineering excellence, tailored to deliver unparalleled accuracy and reliability in tool calibration and measurement for high-stakes manufacturing environments. This machine is built with advanced CNC technology and features a high-precision pneumatic system that ensures consistent pressure application and exact alignment, crucial for achieving precise measurements.

Key Technical Specifications:

- Dimensions: 2140 mm width, 1130 mm depth, 1780 mm height, accommodating various industrial settings.

- Weight Capacity: Capable of handling tools up to 50 kg, supporting a broad range of measurement and calibration tasks.

- Voltage Requirements: Versatile dual voltage system (100-120/200-240 V~), catering to international power standards.

- Frequency: Operates efficiently at both 50 and 60 Hz, adaptable to varied electrical infrastructures.

- Measurement Tolerance: Offers ultra-precise measurement capabilities within ±0.002 mm, essential for precision engineering.

- Operational Environment: Operates optimally within a temperature range of 5°C – 35°C and humidity levels of 5% – 90% non-condensing, making it suitable for diverse operational climates.

- Multi-Axis Control: Features up to 4 axes for comprehensive tool analysis, with an optional rotational axis for detailed tool examination.

- Safety Features: Equipped with emergency stops and safety shields, ensuring secure operations and enhanced workplace safety.

- Connectivity: Includes USB and network interfaces for seamless integration into existing systems, facilitating data transfer and system management.

- Software: Incorporates Zoller's Pilot 3.0 software, which offers an intuitive interface and advanced analysis tools for streamlined operations and precise control.

- Pressure System: Integrated pneumatic system maintains precise tool positioning and stability during measurements.

- Maintenance Features: Optional pressurized air cleaning system to maintain optimal cleanliness and functionality of the machine.

Application and Usage: Designed to integrate seamlessly into industrial settings requiring meticulous precision such as aerospace, automotive, and precision engineering sectors, the Hyperion 500 ensures that every tool is measured with the highest accuracy. This significantly enhances the quality and consistency of production outputs, making the Hyperion 500 an indispensable asset for modern manufacturing facilities.

Other Vendors:

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.